ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFLtècnics Rollstock Pouchers

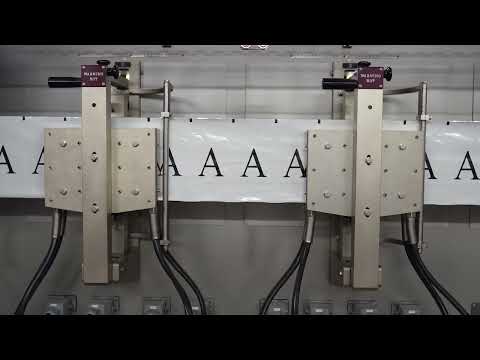

The rollstock pouch machine offers a solid modular design for maximum productivity, reliability, and easy operating. Features on the rollstock pouchers including automatic format changes, an integrated automatic splicing system, and more. Browse through these rollstock pouch machines and watch these systems in action.

Rollstock pouch machines are versatile enough to accommodate:

- Flat pouches

- Stand up pouches

- Doypack, or delta, pouches with a top spout

- Pouches with a corner spout

- Shaped pouches

For inquiries and to learn more about the rollstock pouch machines featured in these videos, contact Bartelt today.

Stand up pouch filled with juice for kids drink. Straw applied to pouch.

Stand up pouches. Reel unwinder, forming module

Piston pump & auger filler, top cutting die partial shape

Flow meter, Label straw system, total shape & flat stand up on same machine without remove cutting die

Tablet filler, Auger and Piston pump. Pick & Place with counting belt.

Flow meter (sauces), CV1 system, spout elevator

Flowmeter. Top valve (choke safe). Total shape, pick & place & cooling tunnel

Auger filler (sugar), 200 ppm, pick & place, grouping belt

Flowmeter (chemical product), 160 pouches/minute, printer, total CIP, pouch counting system.

Horizontal form fill seal packaging machine running printed film.

Tablet filler (Viagra), pick & place, grouping belt

4 side seal Total shaped sachet. Auger filler. Tobacco.

Horizontal form fill seal machine with 3 filling stations, servo driven film feeder, film feed and scissors monoblock system, hand sanitizer, powdered product and tablets.

Pretzel Crisp packaged on large stand up pouch machine with automatic splicing system, bottom perforator, zipper, cooling plate, expanding funnel and more.

Flowmeter, Ultraclean system, Top valve (Choke safe), complete line with check weigher, X.Ray, cooling tunnel and cartooning spider system

Auger filler, ATEX configuration, total gas chamber, automatic splicing system (150ppm)

MHW (Walnuts), thermo printer on reel unwinder, labelling machine

Flowmeter, total shaped sachet with change of line

Stand up pouches. Reel unwinder, forming module

Servo motorized machine, Flow meter (4 heads), duplex corner valve, ITS (Independent Top Sealing jaws), quick and fast format change over

High speed quadruplex horizontal form fill seal pouching machine filling 4 pouches simultaneously.

Pressure application and water submersion for testing pouch seal.

Corner valve applicator, zipper module, Automatic splicing system

Automatic splicing system, Synchronism to MHW, pyramid air blowing, gas flash

Automatic splicing system, Spee-dee auger filler (almond powder), complete line

Quadruplex Piston pump (Pharmaceutical gel), Twin 4 side seal sachets with central perforation, Automatic splicing system

Quadruplex Auger Filler (Coffee), 3 & 4 side seal sachet (up to 300 pouches/minute), Automatic splicing system, pick&place